PRODUCT PERFORMANCE

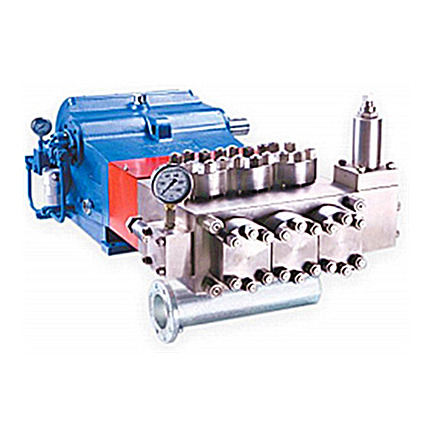

1. For the machine, pump is use the tech. of Germany KAMAT

2. It has big water flow and high pressure advantages

3. Pressure is stable and reliable, easy to be adjust

4. Pure physical cleaning without adding any chemicals

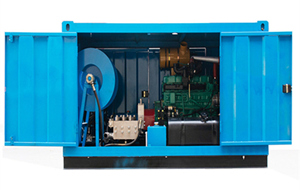

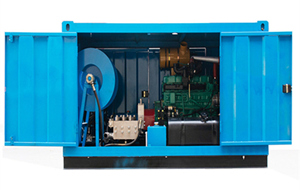

5. We have diesel engine drive and electric motor drive for your choice

Product Advantage:

There are four main methods for removing phosphorus from cold-rolled steel sheets and strips to remove surface oxide scale: pickling, mechanical, deformation and high-pressure water removal. The high-pressure water physics method is used to clean the oxide scale on the surface of the steel plate. There is no acid mist, no dust, and no pollution. Water is recycled, no waste water, and no waste gas emissions. The cleaned waste residue is recycled by the steel plant. High-pressure water phosphorus removal has the advantages of energy saving and environmental protection and is widely used.

Working Principle:

The high-pressure water generated by the high-pressure water jet generating device is sprayed from the sandblasting head through the high-pressure pipeline, and generates negative pressure in the sandblasting chamber. The sand moves to the sandblasting chamber due to the pressure difference, and interacts with the high-pressure water in the sandblasting chamber. Mix, thereby accelerating movement, spraying out quickly, hitting the metal surface, and producing a certain cutting and grinding effect on the metal surface, causing non-body dirt, grease, floating rust, oxide scale, etc. on the metal surface to instantly peel off, thus Make the metal surface reveal metallic luster to achieve the desired surface effect.